At this point, we’ve covered quite a few hop products on the market including Salvo™, Incognito, and SPECTRUM. Each has their benefits and intricacies, but FLEX seems to be one of the easier hop-based extracts to use.

As a flowable extract—hence FLEX—this is a 100-percent, all-natural, concentrated alpha hop product from John I. Haas that is easy to ship and easy to store.

With all of these new hop innovations, breweries need time to experiment and figure out the best practices. With that in mind, we talked with one of the earliest adopters of FLEX, Oskar Blues Brewery, along with Wiseacre Brewing Company to discover the best ways to brew with FLEX, the specific advantages, and the one trick you absolutely need to know.

(Above photography courtesy of John I. Haas)

Affordable, Industry-Leading Brewery Software

What Is FLEX?

Photography courtesy of John I. Haas

Derived from pure hops, FLEX is designed to be a source of bitterness in beers.

Packed with approximately sixty-five percent alpha acids, according to John I. Haas, FLEX comes in a flowable form, making it very easy to use.

“It’s basically an alpha extract,” says Davin Bartosch, head brewer at Wiseacre Brewing Company. “It’s not a paste, but it’s not exactly water consistency either, so it’s certainly easier to measure than other hop extracts we’ve used.”

Since it’s pretty much just a liquid version of all the lupulin glands inside of a hop cone piled up and compressed into a flowable extract, FLEX appears “like the resin in ‘Jurassic Park’ where the mosquitos are trapped, but in flowable fashion,” says Tim Matthew, VP of global brewing at CANarchy Craft Brewery Collective. “Imagine sixty-five million years ago when the resin flowed over a mosquito, that’s what it looks like.”

Oskar Blues Brewery, one of the breweries under the CANarchy umbrella, was one of the earliest adopters of FLEX.

According to Matthews, almost nine years ago Oskar Blues was looking to move to a CO2, alpha-acid extract, but the ones they tried to work with at the time weren’t flowable.

“We’d have to open a can, warm it up, and pour it in, and there was always some loss,” says Matthews.

Coincidentally, at that time, John I. Haas started trialing FLEX. Oskar Blues volunteered to experiment with and test out the product. The results, according to Matthews, were fantastic.

So much so that today, Matthews says over eighty-five percent of the beer in CANarcy brands as a whole (not only Oskar Blues) uses FLEX. “Any beer that has a bitterness addition will use FLEX,” he says.

Reason being there are many advantages of leveraging this unique flowable, bittering product.

The Top 4 Advantages of Using FLEX

Photography courtesy of John I. Haas

These are the main advantages of using FLEX in the brewing process:

1. More Consistent and More Stable

Hops in pellet and whole-leaf form naturally deteriorate over time. That’s just pure science. CO2 extracts, on the other hand, are more stable. “Alpha acids decrease over time, and that’s a commodity you paid, for so if it degrades you have less of it and the cost goes up,” says Matthews.

According to John I. Haas, FLEX can be stored for up to two years without losing its efficacy.

As a more stable product, FLEX ensures that you can mimic those similar bittering qualities you’re looking for from hop pellets or whole-leaf cones without worrying about the quality degrading over time.

Similarly, the qualities and flavors of a specific hop varietal change based on the season and the lot that you use.

Because FLEX is a standardized alpha acid, it is very consistent. “You don’t have a varying amount of pellets from various lots,” says Matthews, meaning “any time you get to have a formula locked in…is an advantage, [because] when you have multiple brewers making products and executing, you want the ingredients to be consistent.”

A consistent product ensures that the recipes you’ve designed for your beers can reach a certain quality and flavor every single time.

Photography courtesy of John I. Haas

2. Better Yield

Another law of brewing physics: The more tangible hops you have in a beer, the less beer you’ll have in the final product.

“Vegetation absorbs wort, so if you don’t absorb wort you get more wort out of the grain you just put in the mash tun,” says Matthews. Since FLEX is a flowable alpha extract consisting of no vegetative material, your final beer should reach a higher yield.

Matthews admits that by batch the return is subtle—about two percent per recipe. But if you factor that two percent into all your beers made for the entire year, “that’s a good amount of money,” he says.

Similarly, Bartosch mentions that the yield savings aren’t super dramatic at Wiseacre. While he does see a little bit better yields on the recipes where he uses FLEX, Bartosch says that, for him, the best cost-saving advantage of FLEX comes from shipping and saving space.

3. Saves on Shipping Costs and Storage Space

Since FLEX is a liquid product as opposed to a solid one, John I. Haas’ FLEX product page reports that there is a “more than seventy-five-percent reduction in product weight compared to standard T90 hop pellets.”

This is certainly true for Bartosch at Wiseacre. “Instead of six pallets of hops, we get one pallet [of FLEX] because it’s all concentrated,” he says.

Plus, that also means you’re saving on storage space. “One of the nicest things about [FLEX] is that it takes up a very small amount of space,” says Bartosch, noting that one pallet of FLEX takes up about four times less space than bags of hops in the cold box. “As opposed to us having a fridge or freezer packed full of even pelletized hops, you can fit the same amount of bittering compounds in a much smaller space.”

And that’s key here because at the end of the day none of this would be important if FLEX didn’t provide the high-quality bitterness you’re looking for in your beers.

4. Better Bitterness and Taste

According to John I. Haas, FLEX in its liquid form improves bitterness over a traditional T90 hop pellet by ten to twenty percent.

The flavor of FLEX is the original reason Wiseacre started using the CO2 extract.

“The type of bitterness we get is nicer,” says Bartosch. “Sometimes you can get a bit of a muddy bitterness. Even with some of the really high-alpha hops just cooking all that vegetative material, you can end up having some unfortunate flavors… So [FLEX] makes a very precise, non-vegetable tasting bitterness.”

This is especially true at Wiseacre where they specialize in lagers. “You don’t want your pilsner to taste like broccoli water,” laughs Bartosh. “FLEX makes it a more delicious, more palatable flavor.”

And that’s even compared to other hop products on the market, not just regular pelletized or whole-leaf hops.

“With a lot of the other ones, the resulting beer tasted one-note or lacked depth,” says Bartosch, who says they’ve experimented with quite a few other hop products at Wiseacre. “Whereas with this particular one you can change to one hundred percent of this product and you get a great bitterness.”

Tips for Brewing With FLEX

Photography courtesy of John I. Haas

When to Add FLEX

We might consider this another advantage, but brewing with FLEX is extremely easy.

A lot of other hop products such as Salvo or SPECTRUM require a bit of prep in order to make them workable in the brewing process.

FLEX, on the other hand, is as easy as popping the top off the jug and dumping the liquid into the kettle.

John I. Haas recommends adding FLEX to the kettle at the beginning of the wort boil “because the product provides hop alpha acids… The isomerization of these alpha acids into iso-alpha acids is still necessary by means of the boiling process in the brew kettle.”

Matthews says that with recipes where you are purely going after isomerized alpha acid, FLEX’s best point of utilization is at a certain time period in the boil. For instance, if you have a sixty-minute addition of hops, use FLEX sixty minutes into the boil. Same with a seventy- or eighty-minute addition.

“Because FLEX has less vegetation, it seems to have achieved maximum utilization that you can calculate at any given addition time,” he says. “Which is key because sometimes with pellets you have a mysterious lack of utilization. Even though you added it at a certain time of boil and it has an alpha acid you’re supposed to get…it is less consistent with pellets and more consistent with those expectations with FLEX.”

How Much FLEX to Add

Since each hopping rate, type of hops used, and hop boiling is different for each recipe at each brewery, there isn’t one widely used, effective formula. But John I. Haas does provide some guidelines.

First, in their “Best Practices Guide for FLEX,” John I. Haas recommends that, when replacing hop pellets with FLEX for the first time, “the alpha acid kettle dosage should be reduced by ten to twenty percent.”

Likewise, “as a general guideline, using the 65% FLEX concentration and 30% bitterness utilization, an initial trial dosage is calculated to be 6.0 grams of FLEX for every 10 BU desired in one barrel of beer (= 1.174 hL beer). Of course, actual utilization may differ, and adjustments are normally required.”

John I. Haas also gives the below basic calculation for hop dosing to use as a jumping-off point:

Kg product to dose = (hL X ppm) / (%U X %conc)

- hL = Final beer volume in hectoliters (1 bbl = 1.174 hL)

- ppm = ppm iso-alpha acids desired in final beer; roughly relates to bitterness units

- %U = Estimated percent utilization = (iso-alpha acids in beer / alpha acids dosed) X 100

- %conc = Percent concentration of alpha acids in hop product

Example: 100 bbl finished beer, 40 ppm IAA desired, 30% utilization, 65% alpha acids in FLEX ((100 X 1.174) X 40) / (30 X 65) = 2.41 kg FLEX to dose

Bartosch said at Wiseacre they would start with whatever alpha units they were going to get and change that to what FLEX is. “So instead of it being whatever hops we were using at the time, which were 17.5 alpha acid, FLEX is much higher, usually sixty-three to sixty-five percent alpha acids, so you can pretty easily do the math to figure out how much FLEX you need on an ounce-per-ounce basis.”

For more information on how to calculate your FLEX dose, refer to this best practices sheet.

Photography courtesy of John I. Haas

How to Add FLEX

Another advantage of this product, FLEX is extremely easy to dose in during the brewing process with very little prep or specialized equipment needed.

If FLEX has been stored cold, you’ll want to bring the extract up to room temperature.

And John I. Haas also recommends mixing the product repeatedly by inverting the package a few times.

But other than that, you just add the calculated amount of FLEX into the kettle.

Although Bartosch found his own convenient, clever way to dose at Wiseacre.

He recommends investing in a shampoo pump. “Whenever you pour this stuff, it’s flowable but it’s not like water,” he says. “You were always leaving some you had to rinse back out of whatever container you were using to measure.”

So Wiseacre came up with its own solution. “The consistency to me was closest to shampoo, so I was like if we can find a way to measure this where we don’t use a measuring cup, that makes this easy.”

Accordingly, Bartosch found a shampoo pump that fit snugly on the FLEX container, figured out how much a squirt weighed, and off he went dosing FLEX that way.

For more information on how to dose with FLEX, check out this John I. Haas article.

What Are the Best Styles to Brew With FLEX?

FLEX is very versatile and can be used when brewing almost any style of beer.

Since Wiseacre is a mostly lager-focused brewery, they’ve had a lot of success using FLEX in lager applications.

At Oskar Blues, FLEX has been used across a wide variety of styles from double IPAs and West Coast IPAs to pilsners.

Two Successful Examples of Beers Brewed with FLEX

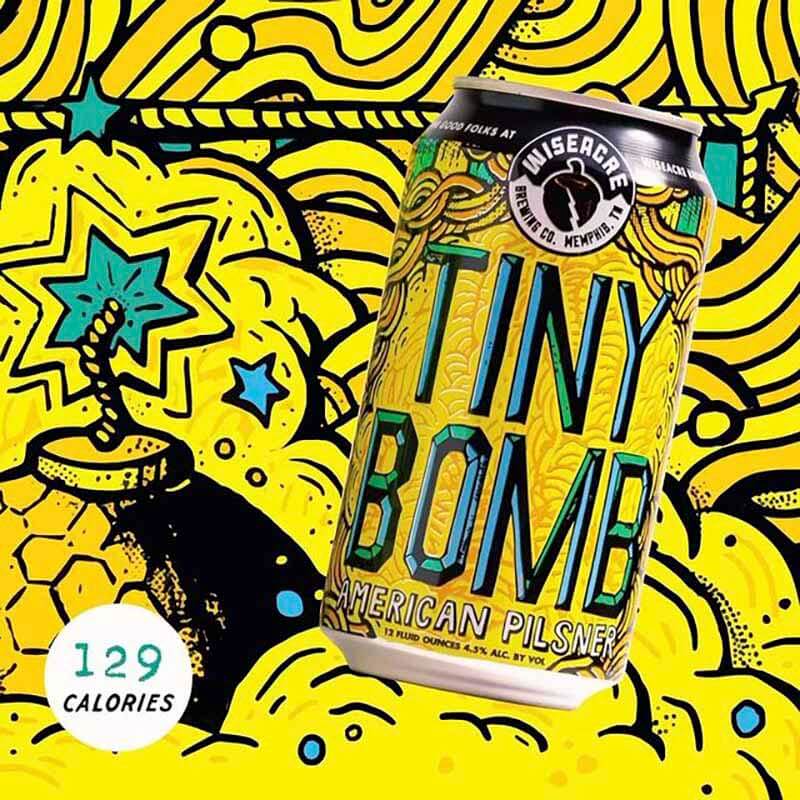

Photography courtesy of @wiseacrebrewingcompany

Tiny Bomb – Wiseacre Brewing Company

Bartosch says their most successful application of FLEX happens in their year-round American pilsner called Tiny Bomb.

“I think there is the biggest difference there because it’s a delicate beer—4.5% ABV, very light pilsner—it’s brewed with honey as well so it’s as light and dry as can possibly be,” he says.

When bittering that beer traditionally, Bartosch says Tiny Bomb would come across a bit vegetal. “[We found the] biggest difference in switching to FLEX because it makes [Tiny Bomb] a much cleaner beer,” he says.

Mama Yella Pils – Oskar Blues Brewery

Similarly, Matthews says they’ve experienced a lot of success with FLEX in Oskar Blues’ iconic pilsner, Mama Yella Pils.

“Our pilsner was the beer that had the best results,” he says. “Traditionally we try to keep to using European varieties throughout the entire boil and moving to FLEX, which has a mix of different varieties—while tentative at first—definitely brightened up the rest of the beer, which was a surprise for us.”

Where Can I Find FLEX?

Currently, FLEX is available in 1kg, 2kg, or 10kg containers.

For more details and information on ordering FLEX, visit John I. Haas’ FLEX product page here.

Brew Your Best Beer. Get Ollie.

A brewery management tool built by brewers and for brewers. Handle everything in your brewhouse from recipe development to cost management. All with one easy-to-use platform. Request a free demo today.