According to a report from Future Market Insights, revenue in the non-alcoholic beer market is projected to reach over $21 million this year and over $45 million by 2033. Expanding at a compound annual growth rate (CAGR) of eight percent in the next ten years, non-alcoholic beer has become a rapidly growing industry segment.

According to NIQ (previously NielsenIQ), between August 2021 and August 2022, total dollar sales of non-alcoholic drinks in the U.S. reached $395 million, a growth of 20.6 percent year over year.

More and more breweries have played this field by making their own mocktails or brewing their own versions of non-alcoholic beer.

For the latter, you can make non-alcoholic beer in several different ways. One gaining traction includes using non-alcoholic yeast, a very specific strain of yeast engineered not to make as much alcohol as beer-specific strains.

Several companies, such as White Labs and Escarpment Laboratories, lead the way on these new non-alcoholic yeast strains, so we sat down with White Labs R&D Manager Fábio Faria-Oliveira and Escarpment Laboratories Co-Founder Richard Preiss to decode everything you need to know about brewing with non-alcoholic yeast.

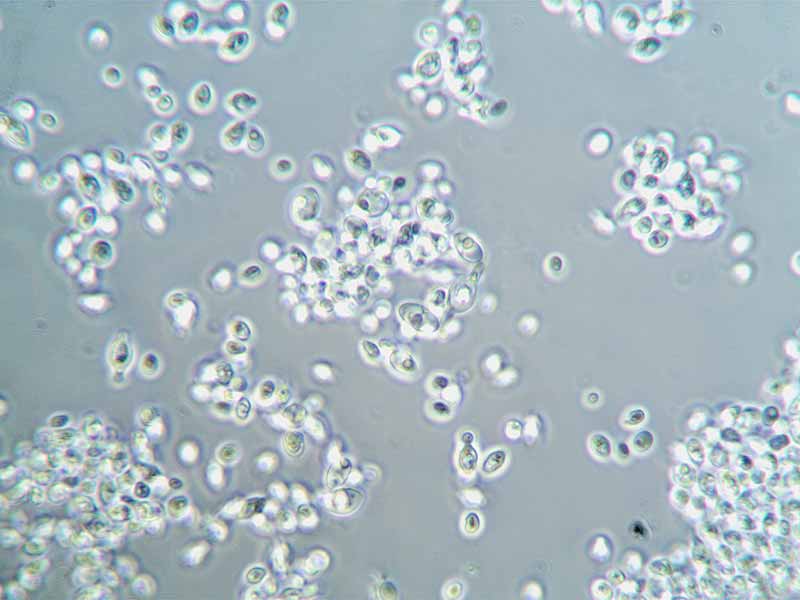

(Photography courtesy of White Labs)

What We’ll Cover in This Piece:

Affordable, Industry-Leading Brewery Software

What Is Non-Alcoholic Yeast and How Is It Different?

Photography courtesy of White Labs

Non-alcoholic yeast is a strain selected to make less alcohol in the beer. “That means the yeast will have a different ability to consume sugars than regular beer yeast,” says Escarpment Laboratories Co-Founder Richard Preiss. “Regular beer yeast is trained and adapted over time to consume different types of sugars.”

As we know, regular wort made with barley is packed full of really complex sugars that normal brewer’s yeast will ferment and break down as energy for itself and to make alcohol.

On the other hand, non-alcoholic yeast has a limited ability to consume sugars found in beer wort. Preiss explains that there are two subcategories.

First, maltotriose-negative yeast, aka yeast that doesn’t consume maltotriose—one of the main sugars found in malt. This non-alcoholic yeast still consumes maltose, making it challenging to work with because it is still the most abundant sugar in beer wort. If you’re using maltotriose-negative yeast, Preiss explains that you need a low-strength wort to keep your [non-alcoholic beer] under 0.5% alcohol, the legal limit for non-alcoholic beer in the United States.

The second type of non-alcoholic yeast is a maltose-negative strain that can’t consume maltose or maltotriose sugars, “so it limits the ability of yeast to consume sugars to only simple sugars—glucose and fructose in the wort, which is usually not very dominant and only twenty percent of the total amount of the wort,” says Preiss.

In other words, maltose-negative yeast is only capable of minimal fermentation. “They don’t ferment all the sugars; they leave some of the ordinarily fermentable sugars behind, which makes it easier to guarantee a beer is less than 0.5% alcohol, which would classify it as non-alcoholic in most jurisdictions,” explains Preiss.

White Labs R&D Manager Fábio Faria-Oliveira explains non-alcoholic yeasts simply “basically prevent alcohol formation by giving them sugars they don’t like and giving them small amounts of things they do like, so they make [non-alcoholic beer] right below 0.5% ABV.”

The Two Big Advantages of Brewing With Non-Alcoholic Yeast

Photography courtesy of Lagunitas Brewing Company

In general, a benefit, according to Faria-Oliveira, is simply giving brewers an easy opportunity to jump into an area of the market that’s growing. “They can compensate for the slowdown in other segments and still tap that non-alcoholic offering in their taproom,” he says.

To illustrate his point, Faria-Oliveira explains that he’s a beer drinker, but his girlfriend prefers not to drink. “If I go to a place with her and there isn’t a [non-alcoholic] option for her, we just move to the next place,” he says. “If brewers can provide that [non-alcoholic] option in their own taprooms or business chains, they can tap into a growing market.”

According to NIQ, non-alcoholic beer accounted for 85.3 percent of sales in the U.S.’s $395 million market of non-alcoholic drinks between August 2021 and August 2022, a 19.5 percent increase from the previous year. That same data showed that 82 percent of non-alcoholic beer, wine, and spirit buyers also buy alcoholic beverages, showing that non-alcoholic drinks target multiple consumer demographics, not just sober or non-alcoholic beer drinkers.

Preiss says interest in non-alcoholic yeasts directly correlates to the growth of the non-alcoholic beer market. “There are a lot of breweries launching these brands with success,” he says, noting he saw the trend accelerate during the pandemic and because more people are sober-curious. “People are looking to be more conscious about when and how much they drink but still look for alternatives that haven’t really changed the experience and socialization.” The non-alcoholic beer fits into that narrative perfectly.

Additionally, while brewers can use a few different methods for creating non-alcoholic beer (about which we go into more detail here)—membrane filtration, vacuum distillation, boiling off the alcohol, or reverse osmosis—all these techniques, for the most part, require expensive pieces of equipment.

Using a non-alcoholic yeast, on the other hand, removes that potentially large investment in special machinery.

“What requires less investment from breweries is when they actually try to use the equipment they already have and [non-alcoholic yeast] to prevent the formation of alcohol,” says Faria-Oliveira. “By having these strains, brewers can tap into that potential; mid-sized breweries don’t need to buy expensive machines to remove ethanol.”

Preiss agrees, calling non-alcoholic yeasts the lowest barrier to entry to non-alcoholic beer. “You can use sophisticated equipment like vacuum distillation and membrane separation to remove alcohol from conventional beer and get good results, but the equipment is really expensive,” he says.

With non-alcoholic yeast, on the other hand, Preiss says, “A brewery can get up and running and at least develop a recipe on a pilot scale without making any significant capital investment.”

What Is the Cost of Brewing With Non-Alcoholic Yeast?

While machines that remove alcohol can cost a quarter of a million to a million plus, according to Preiss, non-alcoholic yeast at the end of the day is just that—yeast.

“Yeast cost as a proportion of the total ingredient cost of beer isn’t much different from conventional beer,” says Preiss.

Will non-alcoholic yeast cost you more than conventional alcoholic-beer yeast? Yes. Non-alcoholic yeast is a premium product, but it is way more affordable than investing in a specialized vacuum distillation or membrane separation machine.

Plus, Preiss points out that “any yeast cost is offset by not producing alcohol and getting taxed on that, making it quite cost-effective,” he says.

The Five Considerations When Brewing With Non-Alcoholic Yeast

Photography courtesy of Elevate on Unsplash

Each purveyor’s non-alcoholic yeast will perform differently, so one of the top tips Preiss can give to anyone looking to try out a new product is to read the literature and follow the manufacturer’s advice. “Follow the instructions, read the manual, and don’t mess around too much,” he says.

You don’t want to experiment and play with non-alcoholic yeast. While you can take liberties and play with alcoholic yeast, non-alcoholic yeast is much more finicky.

Faria-Oliveira explains that White Labs has produced four to five non-alcoholic yeast strains that perform with quirks. “One of them attenuates fifteen percent, the other twenty percent, and the other a little bit more,” he says, noting that, given how much sugar you give them, different strains will make different amounts of ethanol, with some crossing a line you don’t want. “You might make a 0.5% ABV with my strain and a 1% with the next guy’s strain because they have different sugar profiles with different flavors.”

Both Preiss and Faria-Oliveira stressed this point repeatedly: Dot your I’s and cross your T’s with non-alcoholic yeast, and don’t stray from the instructions given by the provider because each non-alcoholic yeast is different within a provider’s portfolio and from manufacturer to manufacturer.

Since non-alcoholic yeast performs differently than conventional yeast strains, these are top things to remember.

Product Safety and pH

Faria-Oliveira says that, “first of all, [non-alcoholic yeast] is completely different from what you know,” so there are a lot of safety issues when using these strains.

With alcoholic beverages, there are hops, alcohol, and sometimes even pasteurization. “Everyone knows beer is very safe, but non-alcoholic beer doesn’t have most of those checkmarks,” he says. “Brewers need to understand [non-alcoholic yeast] is not the same product.”

Preiss explains further that, with limited cell growth in non-alcoholic yeast during fermentation, you won’t see the change in pH like with ordinary beer. Normally, conventional yeast takes care of pH and puts it in a safe range for consumption.

But in this lower-gravity, lower-degree fermentation with non-alcoholic yeast, there is a risk of the liquid being in an unsafe pH range.

For that reason, you need to pay attention to your pH levels. “If you don’t have a pH in the final product below 4.5, it is no longer safe,” says Faria-Oliveira, noting that most food pathogens do not survive below that level. “Traditional brewers are used to very active acidification where brewer’s yeast can drop pH to relatively low levels; non-alcohol strains cannot do that, so if you don’t take that into account, you end up with a product without alcohol that doesn’t have a safe pH and doesn’t have a lot of hops, you actually have a risk, a hazard to people’s health right there.”

Cleaning and Sanitation

In addition to creating a product safe for consumption outside the brewery, Preiss says you need to be hyper-attentive to sanitation inside the brewery.

Because non-alcoholic yeasts are not conventional saccharomyces, handling practices will be different.

“We always encourage brewers to be really careful about sanitization because even your regular brewery yeast, if it gets in, will ferment beer out beyond the point where it is non-alcoholic,” says Preiss.

To Preiss and Faria-Oliveira, conventional beer yeast poses a risky contaminant.

“Because the sugar is still there, almost any bug in your brewery will be better and faster at eating sugar than your non-alcoholic [yeast] strain, so there is a high risk of contamination,” says Faria-Oliveira.

He emphasizes maintaining the best cleaning and packaging practices and highly recommends pasteurization.

Photography courtesy of Alfa Laval

Pasteurization

Preiss and Faria-Oliveira highly recommend pasteurizing (such as flash pasteurization) any non-alcoholic beer made with non-alcoholic yeast. This extra step provides another layer of security to make your non-alcoholic beer safe for consumers to drink and ensure your product doesn’t sour.

“Any little thing will spoil it; it’s that sensitive because all the safety hallmarks of beer are not there,” says Faria-Oliveira. “If those lines are slightly dirty, within twenty-four hours, that will be a sour beer or have contamination.”

For that reason, and since the non-alcoholic yeast causes a mild fermentation, Faria-Oliveira says as soon as fermentation ends, cold crash, getting the beer cold quickly and keeping it cold as long as possible before pasteurization.

While Preiss says the decision to pasteurize is ultimately up to the brewery, Escarpment Laboratories does recommend that if you can’t pasteurize your non-alcoholic beer, you start with a sour beer so you can get the pH quite low and make a safe product.

Extra Sweetness

With non-alcoholic yeast, unconverted sugar will remain in the wort. “That’s why people describe bad non-alcoholic beer as ‘worty’ or sweet, because of the sugar,” says Faria-Oliveira.

You need to figure out a way to balance that extra sweetness.

Faria-Oliveira gives a couple of suggestions. First, start with less grain. “You know the yeast will attenuate to, say, twenty percent, [just as an example]. That means you start with 10 Plato, and you have 8 Plato worth of sugar left behind. That’s a lot of sweetness,” he says. “So you can actually develop the recipe to start with maybe 6 Plato and finish with a 4.5 Plato.”

Additionally, he says you can mash a little higher to create more body to the beer to balance that residual sweetness. “A body to the beer compensates for the lack of other things,” he says. “It will be a thin beer, so play around with the mash temperatures; there’s less fermentables, but there’s a little bit more body to the beer.”

Trial and Error Before Scaling Up

Like uncharted territory, brewing with non-alcoholic yeast will require trial and error.

“You have to play around with … the grains you start with, your target gravity, and your mash schedule so that you have the right sugars you want,” says Faria-Oliveira.

Alcohol changes how you perceive a liquid, from how it coats your tongue to how it interacts with your mouth. “Ethanol is a powerful solvent, so not being there changes how you perceive things,” says Faria-Oliveira. “You need to bring other tools from your toolbox to create perceptions people like.”

The best way to find that ideal recipe is some trial and error.

Additionally, Preiss points out that you shouldn’t expect the flavors with non-alcoholic yeast to be the same as your conventional brewer’s yeast. “Lean on suppliers for advice and, ideally, do a test in-house with the work and your process to make sure you’re getting the flavor you’re after before jumping in whole hog and scaling up,” he says.

The Two Pitfalls to Avoid When Brewing With Non-Alcoholic Yeast

Photography courtesy of Escarpment Laboratories

When brewing with non-alcoholic yeast, here are some hurdles to avoid courtesy of the experts.

Do Not Re-Pitch

Since brewing with non-alcoholic yeast is so sensitive to contamination, Faria-Oliveira and Preiss do not recommend re-pitching.

“It is almost impossible to ferment, harvest, and repeat without introducing something,” says Faria-Oliveira. “Even if you had a good first batch, you can ruin the entire second.”

Preiss says re-pitching isn’t worth the risk because you could create a non-alcoholic beer unsafe for consumption or accidentally introduce your brewing yeast into the pitch, creating an alcoholic beer.

“What will you do with this 1.5% [ABV beer] instead of 0.5% [ABV beer]?” he says. “You’re kind of in this danger zone or uncanny valley where beer doesn’t get made … it’s pretty hard to sell a 1.5% ABV beer.”

Especially if you’re looking to produce a cost-effective non-alcoholic beer, why would you risk dumping a soured non-alcoholic beer or unintentionally producing a by-law alcoholic beer that will be incredibly hard to sell?

“All it takes is one batch that accidentally gets house yeast in it to erase those cost savings pretty quickly,” says Preiss.

Don’t Forget to Track Fermentation

Both Faria-Oliveira and Preiss mention that fermentation will be milder with non-alcoholic yeast strains.

To account for this difference from regular beer brewing, track your fermentations. “Because it’s such a limited ferment, it’s really useful to have equipment that can reliably and accurately measure specific gravity,” says Preiss.

He recommends precision hydrometers or handheld density meters. “For some of those ferments, you might only have a fermentation of a half degree Plato, so you want to track that.”

Again, everything goes back to reading the literature and following the manufacturer’s recommendations.

“There is a need to accumulate knowledge before using [non-alcoholic yeast], because otherwise, it might not match expectations,” says Priess.

Three Non-Alcoholic Yeasts to Try Right Now

Photography courtesy of White Labs

Escarpment Laboratories currently makes one non-alcoholic yeast called NAY (Non-Alcoholic Yeast). Preiss says to make this maltose-negative non-alcoholic yeast, they screened all the yeast in their collection likely to be maltose negative, putting them through fermentation in a wort typically made for non-alcoholic beer—low strength at 6-7 Plato with a warm mash.

Vigorous quality analysis and sensory testing checked for the reliability of the fermented yeast, what the pH drop looked like, and the overall flavor.

According to Preiss, NAY checked all these boxes while producing a fairly neutral flavor. “Other strains on the market are quite estery, which doesn’t work with every style of beer,” he says. “With non-alcoholic beers, if you’re using oddball yeasts, you can get oddball flavors, so we wanted to avoid that and let the brewers let some of the other ingredients shine through.”

NAY avoids those potential off-flavors you might find in other non-alcoholic beers. “The feedback we got was this yeast helped reduce those ‘worty’ flavors obtained with other yeast and no weird ester going on, gets a little bit [of a] fruity thing, but in general, is pretty neutral,” says Preiss.

Preiss points out the other benefit of NAY is the non-alcoholic yeast’s kinetics. “It ferments pretty well,” says Preiss, noting that it’s a super limited ferment of 0.5 to 1 degree Plato, and if you make the wort right, will only take four to five days, “so it’s a pretty efficient process all around,” he says.

Preiss says you should be aware that NAY doesn’t flocculate well, so if you want to make a clear beer, you should filter. “But if you’re making a hazy beer, it’s pretty easy,” he says.

Overall, Preiss calls NAY a “one-size-fits-all [non-alcoholic yeast].”

White Labs makes several strains, but Faria-Oliveira points out two of the most popular—NA All Day (WLP618) and Torulaspora Delbrueckii (WLP603).

Faria-Oliveira calls NA All Day “a workhorse with a very clean profile that is very compatible.”

NA All Day doesn’t have much yeast character, so it works well with hops or anything you add. “If you wanted something where hops shine, 618 is the one,” says Faria-Oliveira, recommending traditional IPAs for this non-alcoholic yeast.

Slightly more expressive, WLP603 creates fruity aromas and flavors. “People describe it like pear or honey aroma in a normal wort baseline,” says Faria-Oliveira. “That one is more yeast-forward and contributes more character and body.”

Overall, Faria-Oliveira says those two White Labs’ non-alcoholic yeasts account for ninety percent of what people buy from them.

A Final Word on Non-Alcoholic Yeasts

While brewing with non-alcoholic yeasts can initially seem a little daunting, the benefits outweigh the extra care and attention you need to pay them.

If you’re looking for more information, check out Escarpment’s Guide on Non-Alcoholic Beer Fermentation or White Lab’s Best Practices for Brewing Low Alcohol/Non-Alcoholic Beers.

And at the end of the day, brewing with non-alcoholic yeast just puts another tool in your toolbox.

Faria-Oliveira boils it down this way: “If you consider wort production and fermentation and have a solution for the stabilization of the product, you considered the overall picture quite nicely.”