For the past year, thiolized yeast has captured brewers’ attention. And for good reason. Companies like Omega Yeast and Berkeley Yeast have engineered strains to unlock thiol precursors, giving your hop-forward IPAs, pale ales, hazies, etc., an even more intense tropical aroma and flavor. So you can be sure that when someone flips the script, designing a new yeast to optimize lagers, we take notice. Lallemand Brewing’s LalBrew NovaLager™ is a completely novel lager yeast strain built to produce lagers with less diacetyl and hydrogen sulfide (H2S), producing cleaner fermentations in less time with a very unique, crisp, refreshing flavor profile.

We sat down with Eric Abbott, technical support manager at Lallemand Brewing, and Aleksei Titov, technical sales manager in Estonia and Russia at Lallemand Brewing, to chat about the advantages of LalBrew NovaLager™ and why it might be the best lager strain on the market right now.

(Above photography courtesy of Lallemand)

What We’ll Cover in This Piece:

Affordable, Industry-Leading Brewery Software

What Is LalBrew NovaLager™?

Photography courtesy of Lallemand Brewing

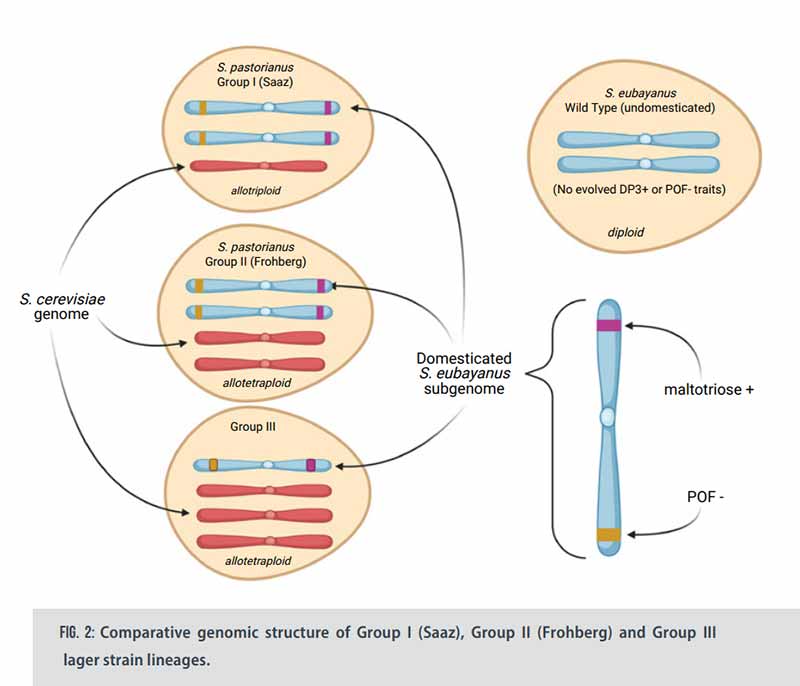

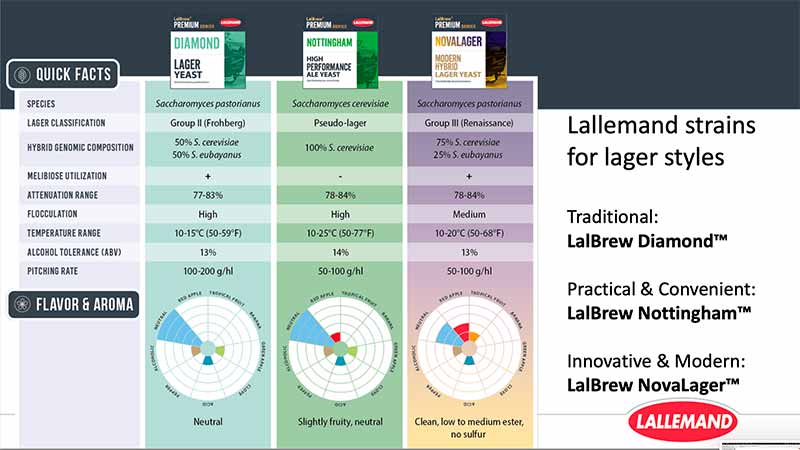

A completely new lager yeast, LalBrew NovaLager™ combines two traditional lager yeasts—Group I Saaz and Group II Frohberg—to produce a Group III Renaissance strain.

“Genetically this is a true Saccharomyces pastorianus lager yeast that is distinct from the traditional lineages and has unique performance characteristics due to a slightly higher percentage of its genome coming from Saccharomyces cerevisiae and Saccharomyces eubayanus,” says Abbott.

Image courtesy of Lallemand Brewing

To create this genetically distinct version of yeast, Lallemand partnered with Renaissance Bioscience Corp., a selective yeast breeding company in Vancouver, BC, Canada.

Renaissance Bioscience Corp. handled all of the non-GMO yeast breeding while Lallemand determined the characteristics they wanted the yeast to produce. “For example, low H2S, very clean profile, high attenuation, broader temperature range, things like that,” says Abbott.

Why Create LalBrew NovaLager™ Yeast?

For a few years now, we’ve been saying that this will be the “Year of the Lager.” And we’re not alone. Popular craft beer magazine Hop Culture predicted that Czech lagers would rise in popularity in the U.S. this year.

And for the first time in 2021, a lager cracked the top ten most-checked-in beers on Untappd, with just over 1M check-ins.

According to Abbott, Lallemand sees lagers as a major opportunity in the craft beer industry. “Going back to our roots… We’re starting to see [lagers] come back into vogue,” says Abbott. “We wanted to provide something that is unique and targeted to the craft beer market [that] solves some of the issues that some craft breweries have with producing lager beers [such as] production time and tank residency.”

Abbott says that with LalBrew NovaLager™ brewers can reduce their fermentation time and turn tanks faster without risking a loss of flavor.

Sounds like a win-win for everyone.

What Are the Advantages of LalBrew NovaLager™?

There are quite a few advantages to brewing with LalBrew NovaLager™.

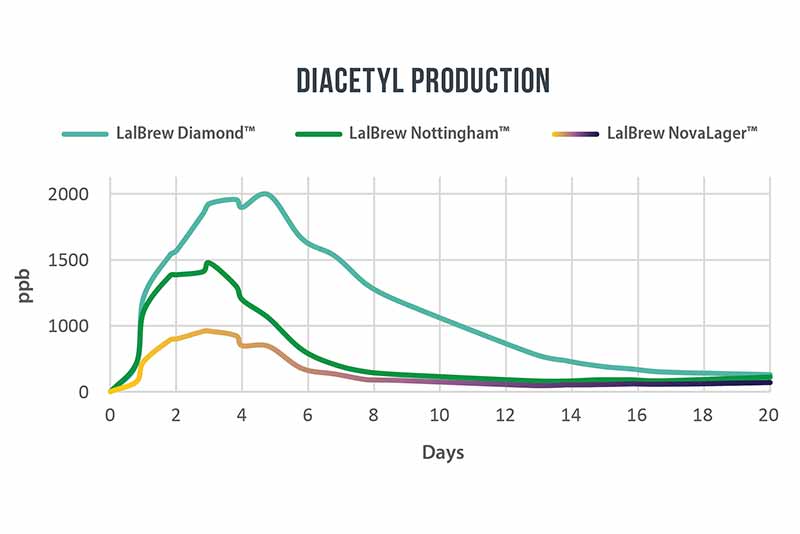

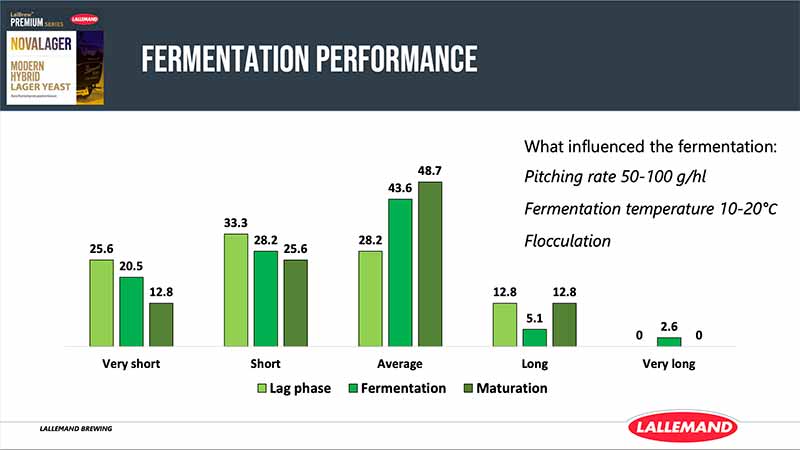

Graph courtesy of Lallemand Brewing

Flavor Profile

At the end of the day, making your beer taste phenomenal is probably one of the biggest goals on your mind.

Renaissance Bioscience Corp. and Lallemand constructed LalBrew NovaLager™ to express a flavor profile “unique and distinct from traditional lineages while still being very clean and refreshing,” says Abbott.

Specifically, this yeast strain produces low to medium esters for more complex hop aroma beers. Additionally, LalBrew NovaLager™ expresses the β-glucosidase enzyme, promoting biotransformation to increase hop flavor.

Graph courtesy of Lallemand Brewing

Additionally, LalBrew NovaLager™ produces less diacetyl because of a higher, more efficient valine uptake, preventing some of those classic off flavors.

A common byproduct of fermentation produced when yeast metabolizes amino acids into valine, diacetyl is often described as one of those off flavors in beer (although not in traditional Czech beers, but that’s a piece for another time).

With ales, yeast reabsorbs diacetyl faster because of warmer fermentation temperatures, but because lagers ferment at cooler temperatures not all of the diacetyl will be reabsorbed.

For that reason, brewing many lagers requires a diacetyl rest, raising the temperature at the end of fermentation to make sure the yeast properly reabsorbs that diacetyl and prevents those “off flavors.”

Because LalBrew NovaLager™ performs closer to a traditional ale yeast strain in these ales you don’t need to worry about a diacetyl rest, contributing to faster fermentation times.

Faster Fermentation Times

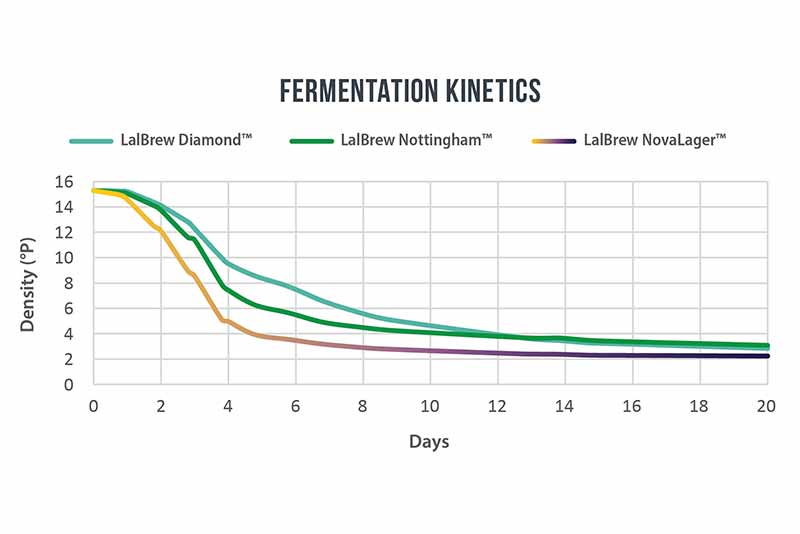

Graph courtesy of Lallemand Brewing

According to Lallemand’s LalBrew NovaLager™ Technical Data Sheet, this yeast strain can complete a lager fermentation in only six days. This number will vary, of course, depending on pitch rate, yeast handling, fermentation temperature, and the nutritional quality of the wort, according to Lallemand.

Still, compared to the normal two weeks or more that it typically takes to ferment a lager, brewing one in about a week makes a huge difference.

Less time fermenting means you get the beer out faster to your paying customers and free up your tanks at a higher clip to keep churning out more beer.

In brewing, time is money. If you can turn your tanks faster than the standard two weeks it takes to ferment a lager, that’s a huge advantage.

So how does Lallemand achieve faster fermentations?

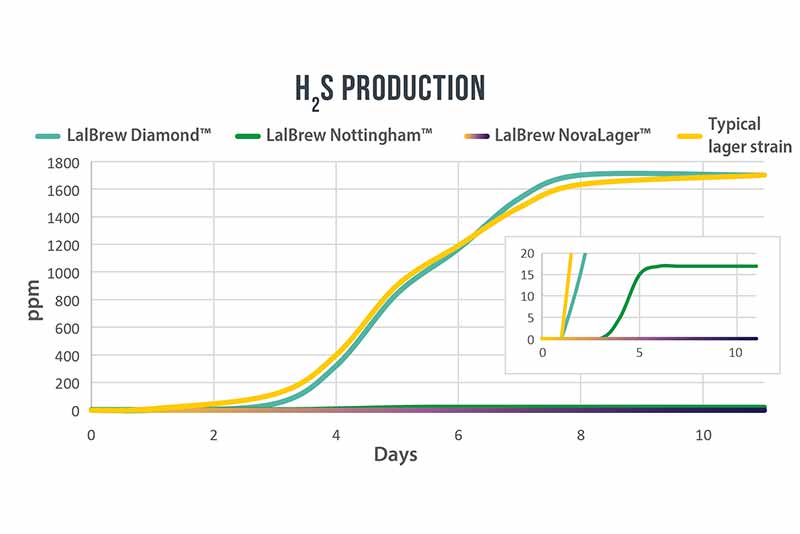

During fermentation, yeast produces H2S. And while with ale fermentations, “H2S is depleted efficiently by CO2 scrubbing during active fermentation and reabsorption by the yeast after full attenuation, with lager fermentation, the cooler, slower fermentations result in less CO2 scrubbing and the bottom-fermenting, medium-flocculant lager yeast does not reabsorb H2S at threshold detection levels,” according to Lallemand’s Lager Strain Selection Best Practices.

Graph courtesy of Lallemand Brewing

LalBrew NovaLager™, on the other hand, uses patented technology from the University of California Davis to produce less H2S, allowing for shorter maturation times than typical lager yeast strains.

And as we already mentioned, LalBrew NovaLager™ allows you to skip a diacetyl rest that will also cut down on your lager fermentations.

Graph courtesy of Lallemand Brewing

Handles Well Under Challenging Conditions

Titov says that one of the best pieces of feedback brewers gave them is that “the strain forgives your mistakes even with equipment or technological [failures].”

This yeast strain can actually continue to perform and produce desired flavors over a varying temperature range. According to Abbott, the flavor profile doesn’t change very much from 10 degrees up to 20 degrees Celsius (50 to 68 degrees Fahrenheit).

This can come in handy if your glycol chiller fails overnight and the temperature of your fermentation rises, for example. “With the traditional lager strain, you might have to dump that batch,” says Abbott. “This yeast is more robust and can handle things like that.”

In a few trials Lallemand conducted around equipment failure and cooling problems with temperature free rises, the yeast performed superbly, producing a clean beer despite the challenges.

Lagers are not easy to make. This is an unforgiving style that can easily show blemishes without a handful of bold, juicy hops or distinct malts to hide behind.

“It’s easier to hide off flavors when a beer is heavily hopped or you add fruit puree,” says Titov. “But lager is clean, it’s supposed to be without any flavors, so it needs to be balanced and perfect.”

Accordingly, if you have equipment issues and the temperature of your fermentation rises, or you’re not implementing a diacetyl rest, for example, “you can get a huge spectrum of off flavors,” says Titov. “This strain is much easier for craft brewers to work with [because] you can ferment at higher temperatures and you’re not even supposed to implement a diacetyl rest, so it doesn’t produce H2S.”

All of these functions make brewing lagers easier for professional brewers using LalBrew NovaLager™.

Energy Savings

Beyond the beer itself, LalBrew NovaLager™ has the potential to save you energy and money.

Because the strain promotes shorter fermentation times, you are cooling less during fermentation, “so the total energy consumption for producing beer will be less,” says Abbott.

With the price of energy climbing substantially in most countries, but certainly in Europe and North America, this cost-saving advantage could have repercussions to your bottom line in the long run.

Abbott noted that it’s still too early for Lallemand to publish any actual savings numbers, but they are currently studying these effects and plan to publish more details in the future.

The Two Best Practices for Brewing With LalBrew NovaLager™

Image courtesy of Lallemand Brewing

You need to keep two things in mind when using LalBrew NovaLager™.

Temperature

First, Lallemand recommends fermenting at an optimal temperature of 10 to 20 degrees Celsius (50 to 68 degrees Fahrenheit).

Pitch Rate

Second, for optimal performance, you should pitch between 50 to 100 grams per hectoliter. Although, Abbott does note that your pitch rate will depend on your fermentation temperature and starting gravity.

“You see those advantages mostly when you ferment at the warmer end of the temperature range, so at 15 to 20 degrees Celsius you can definitely drop down the pitch rate closer to 50 grams per hectoliter,” says Abbott.

So make sure to use Lallemand’s Pitching Rate Calculator to find what works best for your recipe.

What Are the Best Styles to Brew With LalBrew NovaLager™?

Photography courtesy of Lallemand Brewing

Lallemand describes LalBrew NovaLager™ as a modern hybrid lager yeast, meaning they believe that it works best in more contemporary lagers. “If you’re looking for a true European-style lager, this is probably not the perfect strain for you,” says Abbott. “If you want to do a modern interpretation of a traditional style or explore some more of the recently hoppy versions of lagers, this is a great strain for you.”

Lallemand geared LalBrew NovaLager™ towards brewers interested in trying new things, introducing new flavors to styles, and experimenting a bit.

Abbott suggests styles that combine the flavors of yeast and hops—such as Cold IPAs, IPLs, and other styles of that ilk—as perfect for using LalBrew NovaLager™.

“If you are free to play and you want to make additional nuances to older styles and make a unique beer, then this is the perfect choice for you,” says Titov.

Essentially, Lallemand sees LalBrew NovaLager™ as “fitting in a niche that did not really exist,” says Abbott. “This is something that is truly unique in terms of performance and flavor; it’s another strain for brewers to add to their toolkit for brewing any type of [modern] lager.”

A Good Example of a Beer With LalBrew NovaLager™

Photography courtesy of Lallemand Brewing

If you’re looking for a great example of a beer already in the market that utilizes LalBrew NovaLager™, Titov suggests Coronado Brewing Company’s Nado Japanese Rice Lager.

“That’s a good beer to feel the yeast flavor in it,” he says.

But you could also explore a few others around the world, including Hopalaa COLDWARM INDIA PALE LAGER, Evoqe Brewing Do Not Disturb IPL, Eternal City Brewing Beata Quartina märzen, GAS Brew Flight Mode Baltic porter, Nama Brewing Demon Cleanser Cold IPA, and Verdant Brewing Little Mountains We Move Cold IPA, to name a few.

Where Can I Find LalBrew NovaLager?™

If you’re interested in brewing with LalBrew NovaLager™ you can find more information here, check out their Global Distributors map to see where you can purchase, go through the LalBrew app, or email [email protected] for someone to respond to you directly with the appropriate local rep in your region.