Brewing has always been a hands-on craft — a dance between heat, pressure, and precision. But for today’s brewers, managing tanks, temperatures, and timelines often means juggling multiple, disparate digital tools in environments where keyboards and touchscreens just don’t fit. Wet floors, gloved hands, and constant motion make traditional data entry inefficient and error-prone to the extent that people pull back on entering data which limits the use they can get out of their data.

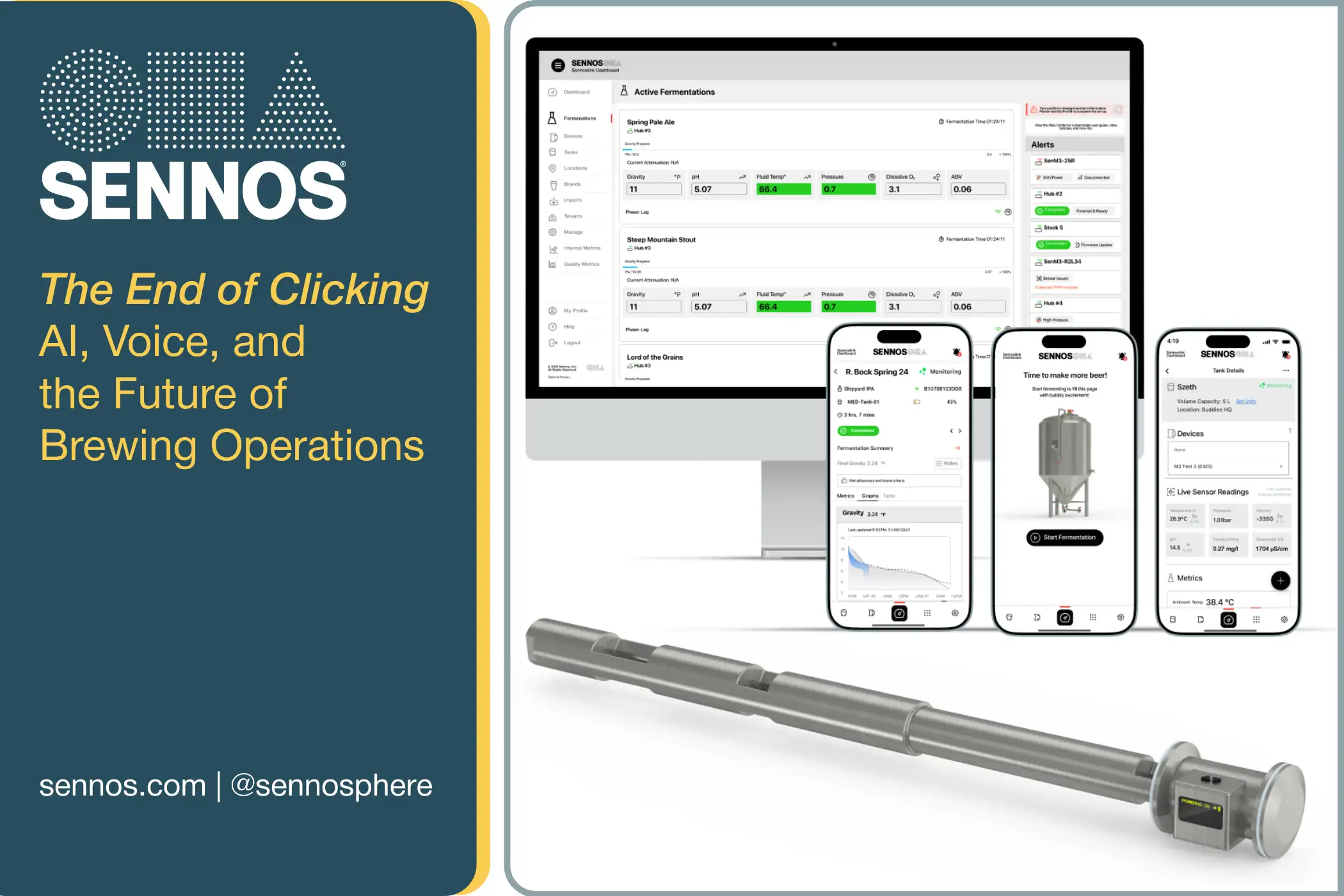

Enter the next evolution of brewery technology: voice-to-text and voice-to-action systems powered by AI. These tools let brewers talk directly to their b brewing software — issuing commands like “Start fermentation tracking” or “Log gravity for this tank” — while keeping both hands on the work that matters most. Combined with visual and contextual awareness, these systems don’t just listen — they understand what’s happening in the brewhouse and respond intelligently.

This isn’t just about convenience. It’s about safety, efficiency, and precision — turning everyday interactions into seamless, automated actions that help brewers focus on their craft instead of their keyboards.

Voice-to-Text and Voice-to-Action in Brewing

Breweries are challenging environments — wet floors, hot equipment, gloves, and constant movement — where typing, even on mobile devices, is inefficient and error-prone.

Voice recognition allows brewers to interact with systems hands-free, issuing commands like “Start fermentation tracking” or “What is this tank’s current fluid temperature?”

With visual and location awareness, the system understands context. When a brewer says, “this tank,” it recognizes which one they mean based on proximity or camera input. All brewing data stays secure in a private cloud, managed by a trusted vendor so users can focus on the batch, not the backend.

These interactions eliminate the need for manual typing or screen navigation, improving both safety and efficiency.

Voice-Activated Automation: The Brewer as the Human-in-the-Loop

Voice as the Trigger, AI as the Action: Brewers issue simple commands, and the AI executes them automatically — starting workflows, logging and/or asking for more data, or adjusting controls.

Human in the Loop: Brewers stay in control. The AI confirms critical actions, surfaces alerts, and requests approval only when needed.

Real-Time Adjustments: If the system detects a temperature drift, pressure event, or other anomaly, it recommends corrective actions. The brewer approves or modifies the response via voice.

Context-Aware Execution: With visual and positional context, the AI understands which equipment or batch the brewer is referring to without extra input.

Automated Data Gathering and Reporting

Instead of typing notes or logs on a tablet, brewers can dictate entries like “Gravity 10-oh-two at 9 a.m.” The AI transcribes, timestamps, and links these notes to the correct tank and batch automatically.

If a data point is missing, the system prompts the brewer: “You haven’t logged the final temperature for Tank 2 — add it now?”

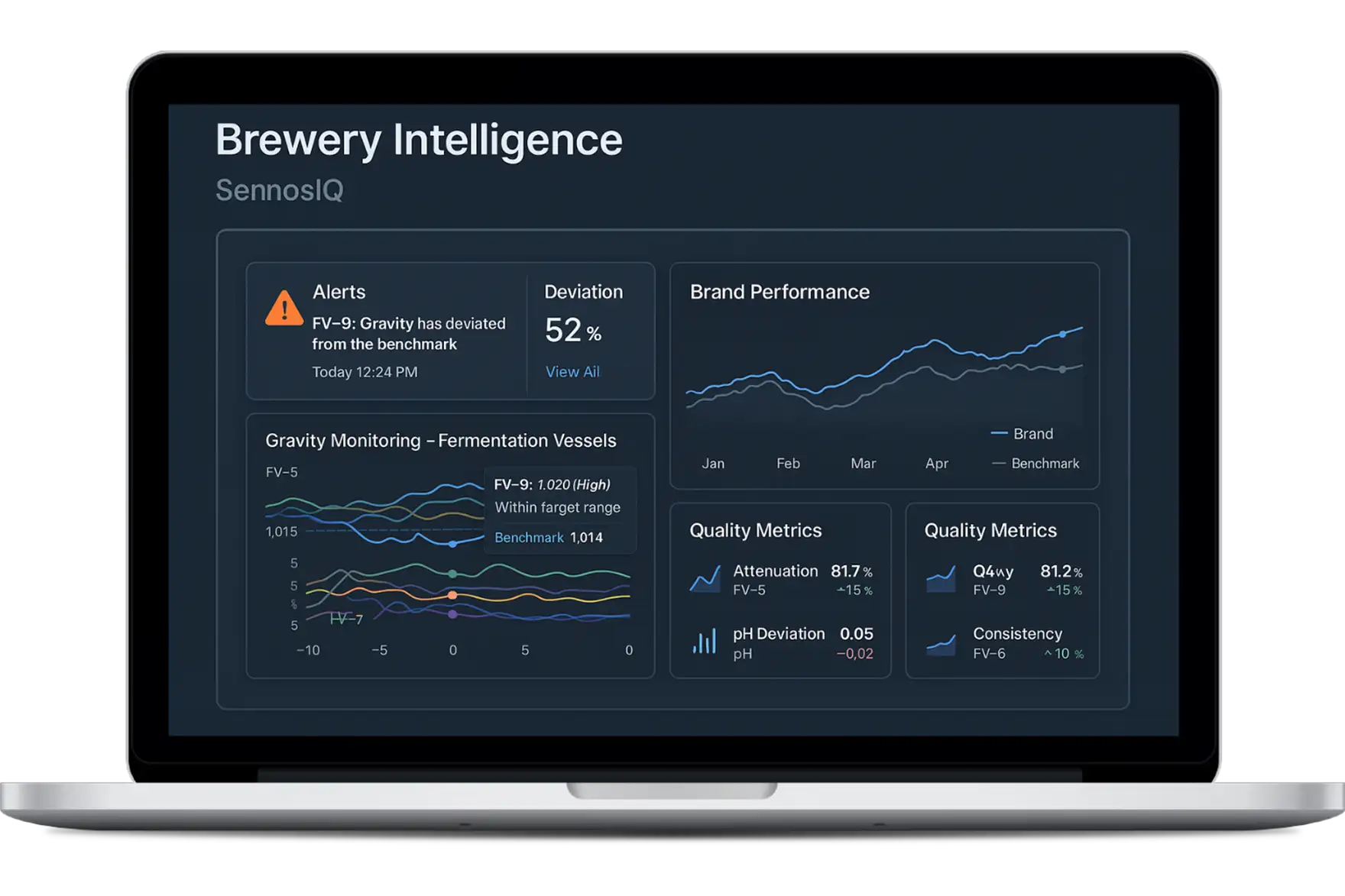

Combining voice, vision, and sensor data ensures every record is complete, accurate, and up to date, which then ensures consistency and provides the basis for efficiency making predictive capabilities. This provides improved reporting and business intelligence as well as lays the groundwork for more predictive and refined capabilities like data integration and augmentation.

GPT and AI Assistance for Task Automation

GPT-powered systems assist in drafting logs, shift notes, or reports — predicting and formatting common phrases automatically.

Brewers can say, “Add that to today’s fermentation log,” and the system formats and files it instantly in the right place.

Over time, the AI learns each brewer’s patterns and preferences, making documentation faster and more intuitive. And that’s not just administrative documentation tasks, but also automated fermentation steps — to use agentic AI to automate hands-on tasks like managing cooling jackets, opening pressure relief valves, or pumping liquid to bright tanks or next-phase filtering.

This reduces repetitive administrative work and creates a more natural interaction with brewing systems.

Seamless Interaction Beyond the Keyboard

Modern AI systems combine voice, vision, and sensor data to interpret brewer intent across multiple inputs and provide real-time feedback and prediction to ensure consistent quality and operational efficiency.

Brewers can interact however is most natural — speaking, gesturing, or showing equipment to the system. Thanks to major leaps in tech, the best voice systems today can detect a brewer’s voice out of the usual bustle in a production facility, making hands-free control actually work in a busy brewery.

Embedded voice assistants in control panels or mobile devices respond contextually: “Adjust fermentation temperature here” or “Show yeast health for this batch.”

The result is a brewing system that feels intelligent, responsive, highly effective, and will ultimately become indispensable in day-to-day operations.

Ready to Learn More?

For more information about Sennos and the future of fermentation technology, get a free, live demo with a real Sennos human.

About Partner Provided Content