If you serve beer either off your tanks or in a package at a taproom, it’s crucial that you keep track of all your front-of-house sales.

That’s obvious.

But what hasn’t been so simple is actually figuring out and reporting on how much beer you sold out of your taproom and how that reconciles with the beer you’ve made in the brewhouse.

Currently, you might be managing everything in Google spreadsheets and, at the end of every week or month, you have to sit down and try to make everything match up.

Or when you move product from your production cooler to the taproom walk-in, you’re making your bartenders write down names and numbers for you.

You can see how the opportunity for error and headaches greatly increases.

Which is why Ollie Ops, a brewery software management platform “Built By Brewers, For Brewers,” specifically designed with brewers in mind, has made front-of-house invoicing easier than ever before. So you can get back to doing what you do best: brewing and selling beer.

Affordable, Industry-Leading Brewery Software

The One Reason You Should Stop Using Spreadsheets to Track Your Front-of-House Sales

Google spreadsheets make your life harder.

That’s pretty much the gist of it. In an industry built on turning tanks and managing time, working smarter and not harder is something that every brewery owner needs to take to heart.

Do you really have ten minutes in your day to sit down and try and figure out how much beer was moved from your production cooler to your taproom, how much you sold of that beer, and how that affects your cost of goods?

Most likely not.

Do you really have time to update your ridiculously large Google spreadsheet every time a beer is taken out of your inventory, whether for distribution or front-of-house sales?

Probably not.

Even if you do keep a meticulous spreadsheet of all this data, do you really have time at the end of the month to do a bunch of calculations and somewhat guess what was actually sold to the front of house?

Maybe, but that doesn’t sound like a particularly constructive approach when running a business.

It’s something Dustin Jeffers, Ollie brewery consultant who previously worked at 3 Sons Brewing Co., found frustrating.

Jeffers says if he wanted to transfer beer from the production cooler to the tasting room cooler, but not sell it yet, “that was a huge pain and really hard to refund yourself.”

He would literally have the bar staff write down what and how much of what beer moved where on a piece of paper. “[But] they’d just write pils,” he says. “I’m guessing it meant Ocean Park Pils, but we also had an Italian pils and two other pils. And just reading people’s numbers is horrific.”

It was an imperfect system that caused many hurdles along the way. When people are forced to write down quantities of beer moved, it can lead to a lot of discrepancies.

“Did we do 10.2 gallons or 100.2 gallons?” says Jeffers, who notes that this recurring issue became so annoying that he would actually have people give a handwriting sample when they interviewed at the brewery.

And there were ripple effects….

“If I found ten minutes in my day to sit down interrupted and put in data, I’d have to get up, try to figure out who wrote it, search around the brewery to see if they’re there, and maybe it was from two days ago and they didn’t know what the number was,” says Jeffers. “It messed up my flow because we’d have to go hand count, check inventory, see if it’s right. So simply typing two numbers turns into a five- to ten-minute flow disruptor.”

And Jeffers isn’t the only one to run into these problems.

He says he’s seen this elsewhere such as at a brewery in California that didn’t have a great way to execute their front-of-house invoicing with their current Ekos platform.

“Their numbers are always off,” says Jeffers. “It’s hard to sell in the system.”

How to Create a Front-of-House Invoice in Ollie Ops

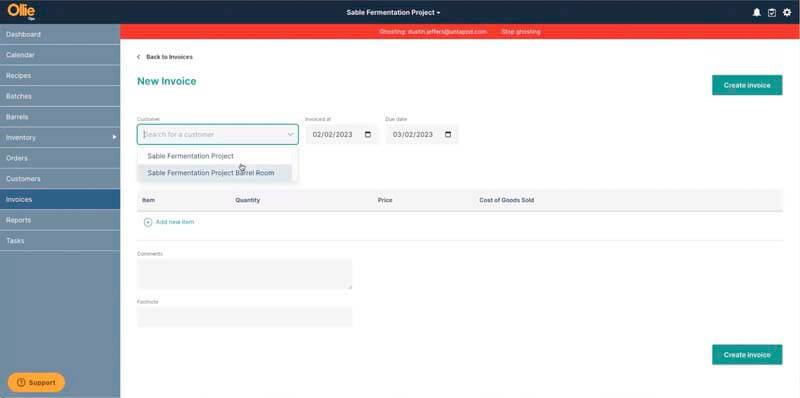

A screenshot showing how to create a front-of-house invoice inside of the Ollie Order dashboard

Because Jeffers had experienced this problem personally and heard about it from others who worked in the industry, he helped push for a solution with the help of Ollie.

“With what we built, you can create customers, which are your tasting rooms…and you can sell to yourself,” he says.

According to Jeffers, with Ollie’s front-of-house invoicing tool, you just make an invoice, choose your date, choose which tasting room it’s going to, add a time, and all the finished goods will pop up with their lot codes, how much you currently have on hand, your cost per item, and the cost of goods.

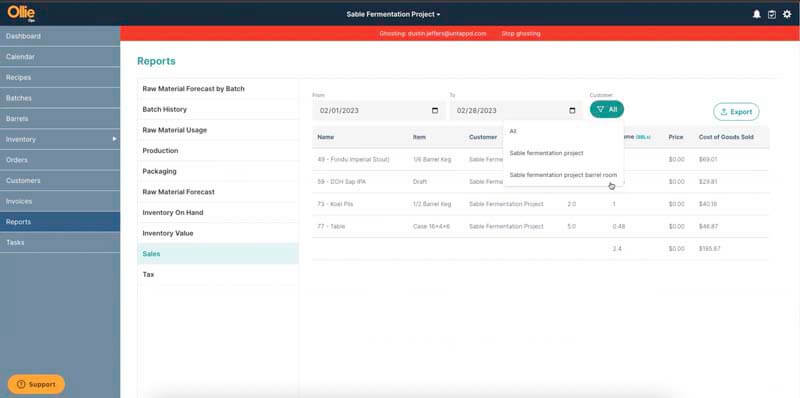

A screenshot of the reporting sonsole inside the Ollie Order dashboard

It’s that simple.

At this point you can download a PDF of the invoice to keep track of what was sold in the tasting room.

Another key feature of this tool is that it gives your brewery the ability to serve beer out of serving or brite tanks.

But perhaps the most important part of Ollie’s front-of-house invoicing capabilities is that you can easily determine the cost of goods on any beer sold out of your tasting room.

“As you’re doing sales to the front of house, whether that’s kegs or brite beer, [you] always see what cost of goods sold looks like,” says Jeffers. “We also have a sales report so you can…choose any date range, look at all the different tasting rooms, and be able to see batches of beer sold, the package type, who the customer was, and how many units sold.”

Ollie’s front-of-house invoicing makes it easy to calculate the cost of goods sold and determine exactly how much revenue you brought in from that tasting room.

It’s just one of the seemingly small yet immensely impactful features of a brewery management software made by other people in the industry who understand the unique situations brewers and brewery owners deal with every day.

The Three Best Advantages of Front-of-House Invoices in Ollie Ops

1. Keeps the Most Accurate Cost of Goods Sold Reporting

By far and away the best part of Ollie’s front-of-house invoicing is the capability to understand with precision how much revenue you’re generating in one or multiple taprooms.

“You’re able to keep a more accurate look on what finished goods inventory is instead of sharing up spreadsheets at the end of the week or month.”

Whereas spreadsheets can get tiresome and unwieldy to maintain, with Ollie’s front-of-house capabilities you can easily and accurately keep track of all your beer sold.

“Because you do have batch-to-batch variance, we make it really easy to figure out what your cost of goods sold is,” says Jeffers, giving the example that one batch may end up at $20 a sixtel while the other may be $21 a sixtel. “That’s really hard to keep track of on a spreadsheet or it has to be a very large spreadsheet; we do all those calculations for you.”

It basically means you have an easier, more accurate way to control your records.

2. Saves You Time From Using Spreadsheets

All that effort you’ve put into maintaining spreadsheets can miraculously disappear with just a couple clicks in the Ollie backend.

“It’s a pretty simple tool,” says Jeffers. But its ripple effects are massive.

For Jeffers, if he had a tool like this when previously working at a brewery, he wouldn’t have to worry about tracking folks down to make sure the numbers were accurate or painfully try to read handwritten notes about what kegs were moved from production to the taproom.

This front-of-house invoicing capability removes all those hurdles.

3. Gives Your Front-of-House Manager Better Oversight

Most likely, as the brewery owner, if you’ve been using spreadsheets in the past, you are the one who maintained it.

Your front-of-house manager didn’t have access to QuickBooks, so it only made sense for you to handle all of the recording, reporting, and calculations.

Here, you can have as many users as you want in Ollie’s system. If you create your front-of-house manager as a user, “they can go in, do these sales, see what they have in stock, and do the sales all in one system without switching between a paper log of all the kegs and packaged beer moved over while looking at one of your spreadsheets,” says Jeffers. “It’s all in one place.”

At the end of the day, Jeffers says that everything we build should be able to accurately show you on an invoice how much money you made on that beer, what it cost you, and what your profit was.

“All the bells and whistles is just to make sure your numbers are correct, your volumes are correct, your cost of beer is correct, you know where it goes, and that final piece is correct.”

Just Another Way Ollie Makes Brewing Better

At the end of the day, paperwork is sometimes a necessary evil of running a brewery. With the capabilities to easily generate invoices from the front of house, Ollie Ops and Ollie Order have taken a stressful, annoying task and turned it into an easy-to-use, streamlined process.

Ready to get back to brewing better beer? Get Ollie Ops or Ollie Order.